Our advantageous location places us in close proximity to iron ore and coal mines, significantly reducing transportation costs for key raw materials like Iron Ore and Coal required for sponge iron production. Notable distances from nearby coal mines include Talabira mines (14 km), Lakhanpur Mines (60 km), Belpahar (62 km), and Samleshwari (45 km). Additionally, we are approximately 300 km away from Joda Iron ore mine and 280 km away from Keonjhar.

Beyond our strategic positioning, our plant is conveniently located near consumers of finished products, serviced by both road and rail modes.

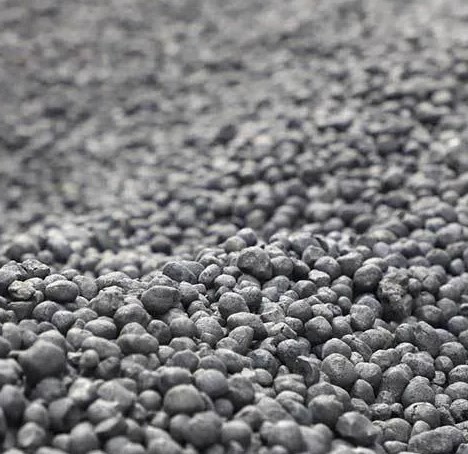

The company has successfully commenced commercial operations with Sponge Iron Unit-I of 100 TPD and Unit-II of 350 TPD, supported by a captive power plant with a total capacity of 18 MW. This includes a 12 MW Waste Heat Recovery System and a 6 MW Atmospheric Fluidized Bed Combustion (AFBC) unit, equipped with advanced boilers from Thermax and turbines from Siemens. Additionally, our Coal Washery has a current beneficiation capacity of 0.70 million metric tonnes per annum (MMTPA), with expansion plans underway to increase this to 5.00 MMTPA, further strengthening our integrated operations.

Our in-house Private Freight Terminal (PFT) is one of the leading facilities within the East Coast Railway network, featuring a 7 km private siding with four operational platforms and the capability to handle over 200 rakes per month. This terminal significantly enhances our logistics efficiency, providing seamless connectivity for bulk cargo such as coal, iron ore, and sponge iron. The plant’s strategic positioning not only ensures cost-effective sourcing of raw materials but also provides proximity to key consumers of finished products, allowing for timely and reliable deliveries via both road and rail. Together, these infrastructural strengths position Aryan Ispat and Power Pvt. Ltd. as a vertically integrated and logistics-efficient industrial powerhouse in Eastern India.